-

Geotechtronics GmbH

Pollinger Str. 3 • D-82362 Weilheim i.OB -

Office hours

Mo-Sa: 9:00-18:00

Inkjet processes as marking systems

When it comes to labelling products, packaging and other goods quickly, easily and economically, there is no way around ink. Laser systems are not practical enough for everyday industrial use and even the cost advantage given in the home sector melts away completely with high print volumes. Other types of marking, e.g. engraving or branding, are only suitable for selected substrates (metal, wood) and cannot be used generally - certainly not for the most common applications of cardboard and plastic.

In inkjet processes, two slightly different concepts have become established in practice (the third area of thermal printing processes hardly plays a role in the industry): Systems with drop-on-demand (DoD) processes and continuous inkjet technology. In industrial terms, the drop-on-demand process is almost exclusively the thermal inkjet concept (from Hewlett Packard). Here the print head and ink tank are combined in a single, compact cartridge. As the name implies, a drop of ink is ejected from the printhead only "on demand" and thrown onto the substrate. The print head can address each individual ink nozzle directly from the outside via electronic contacts. This design enables maximum flexibility and allows miniaturisation, which is what makes real hand printers possible in the first place. Due to the principle-based separation of the printing unit and the control unit, this drop-on-demand process can be used for almost any application (printing of several pages simultaneously, huge ink selection, etc.).

The continuous inkjet process, on the other hand, uses a continuous ink jet, which - to put it simply - is broken down into tiny micro-droplets, which can be selectively charged and thus "deflected". Only droplets with the appropriate charge then hit the outlet and are thrown onto the substrate. All other droplets are collected and returned to the ink supply.

Continuous Ink Jet CIJ vs. Drop on Demand - which is better?

Advantages of Continuous Ink Jet (CIJ)

CIJ systems are unbeatably economical as all unused ink is recycled back into the printing process. There are no vapours that cause ink loss. The technology, similar to the old cathode ray tube TV, is long proven and robust at the same time. It allows extremely high processing speeds.

These advantages make CIJ particularly suitable where there are very large quantities of objects to be printed, i.e. in industrial mass production in almost uninterrupted operation. Such systems are therefore often integrated directly into the production lines and are rarely "retrofitted". Continuous inkjet is also more maintenance-intensive than drop-on-demand processes, because with DoD the entire printing unit is regularly replaced along with the cartridge. This does not require any special expertise. CIJ is expensive to purchase and pays for itself over time through the smallest advantages in printing costs.

Advantages of TIJ (Drop on Demand)

Thermal inkjet technology was the breakthrough for drop-on-demand labelling systems. It was only through this that small and inexpensive systems became available on a mass scale. TIJ is also almost completely maintenance-free - after all, the print head is also replaced regularly when the cartridge is changed. Today, the purchase costs have become very reasonable. TIJ hand printers are already available for a few hundred euros, and stationary systems can sometimes be purchased for slightly less than 1,000 euros.

Even if the printing costs are somewhat higher for drop-on-demand labelling systems, this gives you more flexibility. In handheld printers, TIJ can be used for several work steps at the same time, such as labelling shipping cartons with subsequent labelling of pallet foiling or direct printing on the transport pallet. TIJ is also very robust against external influences such as temperature, dust or even humidity. Its compact design makes it very suitable for retrofitting in existing production lines. Multi-head systems can then also mark objects simultaneously from several sides. The same methodology can be used to set up redundant marking systems, thus enabling a completely uninterrupted printing process when changing cartridges. Special bulk systems for drop-on-demand technology also make it possible to use large, external ink supplies, thus making even larger print volumes more economical.

NasaJet® Drop on Demand handheld systems

NasaJet® handheld printers are the right choice if you want to print on products or packaging frequently with little initial effort and cost. In the warehouse, on the production floor or in the shop, the mobile hand printer can quickly and economically print text, numbers, images and barcodes (QR codes) on anything. The principle is suitable for almost all solid materials, be it metal, wood, stone or of course just paper, cardboard or plastic. This makes it easy to apply a wide variety of markings with a single device. With the favourable purchase price and the very robust technology, the NasaJet®s are ideal for commercial use. The range of functions - multi-line printing, printing of images, barcodes or consecutive numbers - is in no way inferior to much more expensive competitor products. Print templates are created quickly and conveniently directly on the device with the help of the built-in touchscreen and are also saved there. Your own graphics and logos can of course be transferred to the device via USB stick.

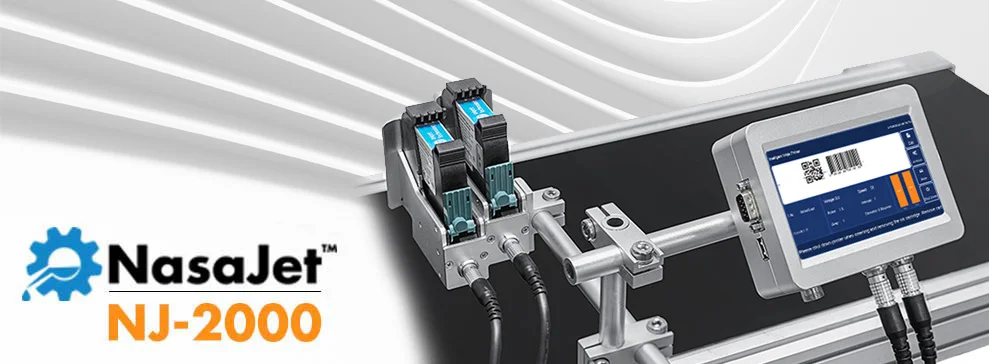

NasaJet® NJ-1000 and NJ-2000 drop on demand marking and labelling systems

Also for larger production quantities or for subsequent integration into already existing production lines, we offer a professional yet economical solution with the models NasaJet® NJ-1000 and NJ-2000. The separate control and printing units allow installation in existing production lines with a maximum printing speed of up to 60m per minute. The print units can be flexibly positioned.

The control unit allows the creation of complex print templates via the integrated touch screen, which also remain stored and retrievable directly in the unit. The output of best-before dates, serial numbers or barcodes is thus fully automated and the labelling costs remain economical.

We would be happy to answer any questions you may have about our NasaJet® Drop on Demand systems or to give you a personal demonstration of the NasaJet®.